What is peeling fluid? Stripping fluid specifications, configuration methods, features and application advantages

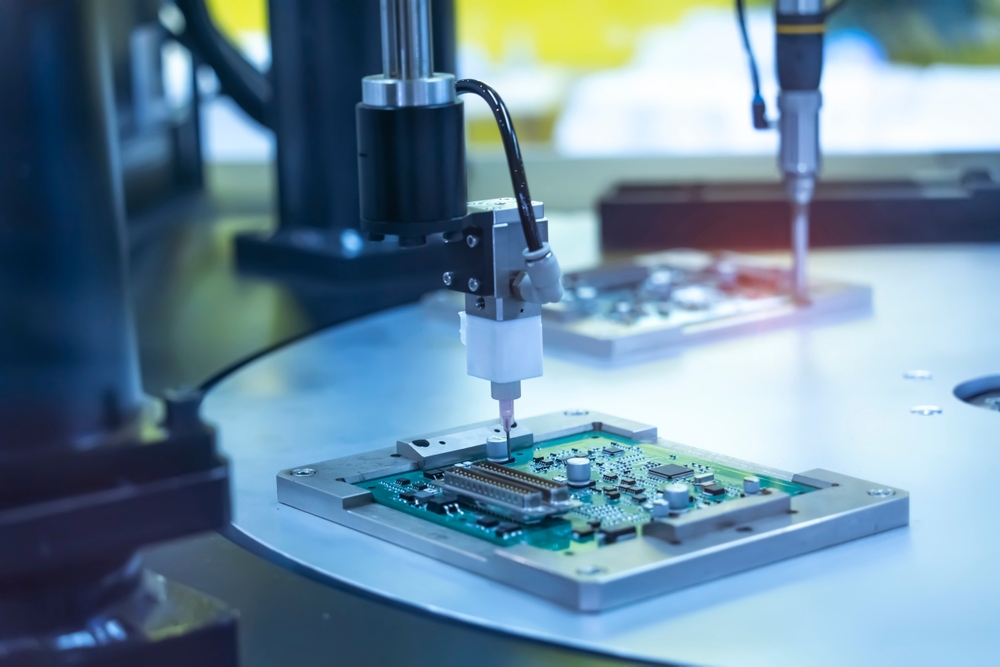

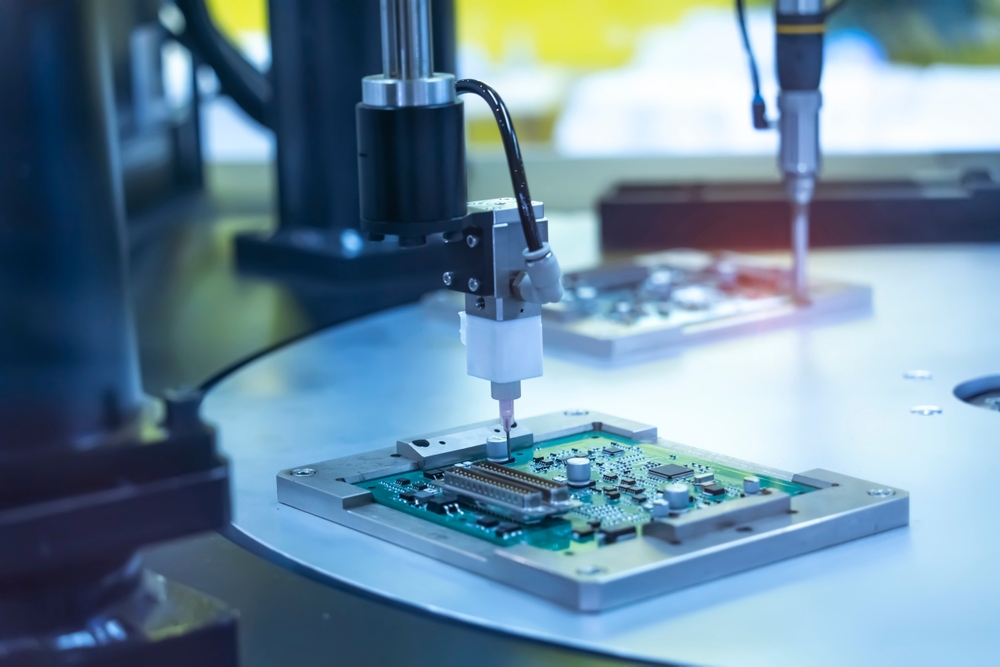

The quality of the stripping fluid plays a key role in stripping the dry film during the manufacturing process of carrier boards and printed circuit boards (PCB). This article will delve into the key information on the specifications of the stripping liquid series products in the PCB process; the configuration method, characteristics, composition advantages and application uses of the stripping liquid, etc., to meet the wiring formation and material applicability of the company's various processes. demand to continuously improve the performance of final products.

What is peeling fluid? Key information on specifications of peeling fluid

Stripping fluid is a process chemistry specifically used in the photolithography section of PCB circuit manufacturing processes. Its main function is to peel off the developed dry film, promote cracking and peeling of the dry film to clearly reveal the circuit pattern, which affects the efficiency and quality of the process. The essential.

Specifications of peeling liquid: Take SA-12 and SA-13 double-dose film-breaking type peeling liquid as an example

The application specifications of the peeling fluid are mainly determined according to the film thickness, required concentration and other process requirements. The product specifications of Zhipu Co., Ltd.'s product─"SA-12, SA-13 double-agent film-breaking type peeling fluid" focus on Information as an example:

1.Peeling products

- Product name:SA-12、SA-13

- Product type: double-agent film-breaking film stripping liquid (organic dosage form)

2.Application film thickness

- Shredded film size 0.1mm~1mm

3.Peeling ability

| Mark line width/line spacing(L/S) |

MP 8/8、NPI 5/5 |

| Dry film thickness |

25~200um |

Echem also has SA-06, SA-07 and organic dosage forms SA-22, SA-23, etc.SA series peeling liquid products;It can also be customized according to customer needs. For further details, please contact Contact our company’s business personnel。

How to prepare peeling fluid? Instructions for the preparation of double-dose peeling liquid

When configuring the stripping solution, it can be diluted with water, and a combination of organic alkali and solvent can be used to strip and develop the dry film in the lithography section. The following takes two dosage forms, SA-12 and SA-13, as examples to illustrate their ingredients and configuration:

- The first dose of organic base penetrates the dry film

- The second solvent moisturizes the dry film to peel it off

The specifications of the SA series stripping agents developed and produced by Zhipu Enterprise are all water-based products, and the configuration can be adjusted on a case-by-case basis on-site to correspond to equipment with different line lengths and different process requirements.

What are the features and ingredients advantages of peeling liquid? Take SA-12/13 film stripping liquid as an example

SA-12/13 stripping fluid is the industry's pioneer non-toxic organic product for SAP. It can correspond to the target line width and line spacing process capabilities of wafer-level system-in-package L/S 5μm/5μm, and meets the latest shrinkage of PCB technology. Chemical development needs. It also has the following ingredient advantages:

Advantages of ingredients of SA-12/13 peeling liquid

- Does not attack equipment and reduces maintenance frequency: The organic dosage form adopts a non-toxic formula and has a low copper corrosion rate. It does not damage copper, prevents discoloration, and reduces equipment maintenance frequency.

- Meet the needs of advanced processes: excellent dry film removal ability, clean and residue-free copper surface after processing, which can meet the needs of advanced processes such as fine lines and DFR miniaturization of closed areas.

- The equipment investment is low: the equipment only requires 3 to 5m short-term cables and has the advantages of organic double-dose formula application and easy online management.

- Low COD: The solvent formula does not contain acutely toxic substances, and the COD index is lower than that of other manufacturers. Wastewater treatment is easy and does not require subsequent stratification treatment, helping companies to smoothly transform into ESG sustainable production.

What are the uses of peeling fluid and how to apply it?

E-CHEM SA series stripping liquid products are mainly used in carrier boards and printed circuit board (PCB) circuit processes to strip and develop dry films in the photolithography stage. The operation process is as follows: swelling, peeling, and dissolution.

In addition to being mainly used for dry film stripping in the lithography stage of the mSAP and SAP processes of Substrate carrier boards, SA series products can also meet the dry film process needs of mainstream brands such as Hitahci, Asahi, and Dupont. It also has the following application advantages and is the first choice of raw materials for enterprise process upgrades:

- Good breadth of industrial application: operating conditions such as concentration and time can be determined according to film thickness, and can also be used in various production line processes such as CSP, FCBGA, PCB, ceramic substrates, etc.

- Excellent process imaging and cleaning capabilities: Equipment and board surface cleanliness are both excellent, and film slag is easily removed after film stripping, which can meet the needs of wafer-level system-level packaging.

Peeling liquid|E-CHEM

芝普企業股份有限公司 E-CHEMWe attach great importance to pursuing the improvement of process technology and innovative industrial development prospects with our customers. We have professional-scale laboratories, clean rooms and inspection instruments. Through the professional capabilities of our R&D and technical teams, we can meet the needs of customers in local production, supply, and testing in Taiwan. Develop a series of customized requirements for products

E-CHEM is one of the few channel service providers with the capabilities of formula development, customized production and quality inspection, providing services includingStripping liquid and other process materials with stable quality can meet the company's long-term and stable complete supply needs of process raw materials in one stop.

Based on the corporate philosophy of integrity, dedication, and sustainable management, E-CHEM continues to optimize existing products, develop new materials, and actively implement corporate social activities, hoping to become the best partner in the minds of customers and suppliers.