What is photoresist? Analysis on the components, differences, usage methods and industrial uses of photoresists and photoresist removers

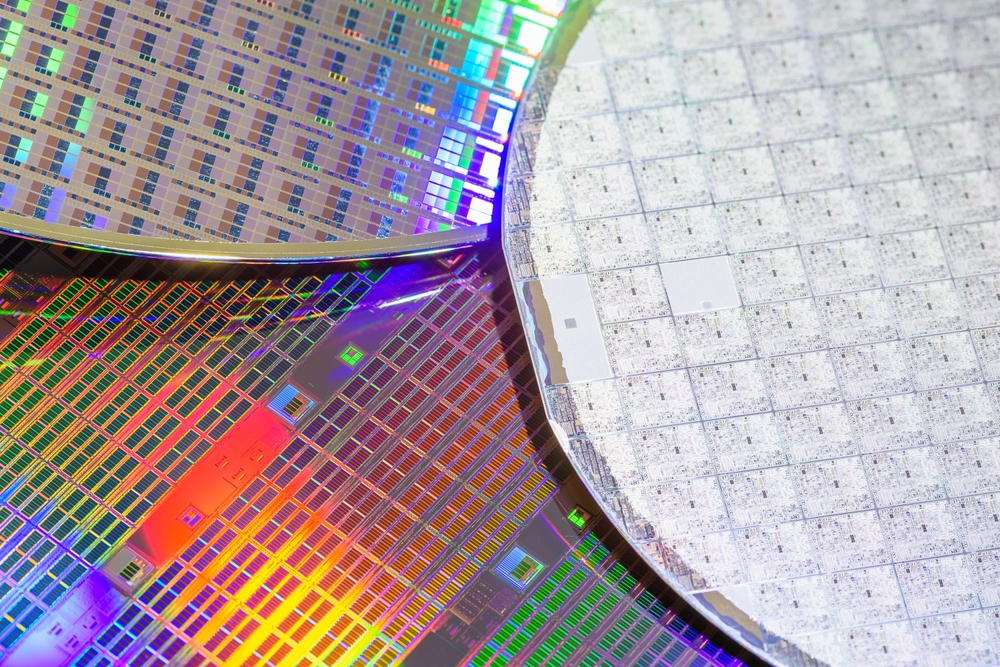

Photoresists and photoresist removers are key materials used in industrial processes such as semiconductors and optoelectronics. This article will delve into the composition and principles of photoresists, and introduce the differences between photoresists and photoresist removers, usage methods, industrial uses, and trends to help you understand how to improve process efficiency from the material side and help companies respond to advanced semiconductors. The future development trends of the semiconductor industry include increased product demand, miniaturization of wafer etching processes, and ESG sustainable industry transformation.

What is photoresist? Photoresist composition and principle description

Photoresist (also called photoresist) is mainly used in industrial processes such as electroplating or etching. Photoresist is generally a photosensitive material composed of polymers, solvents, photosensitizers and other ingredients, and reacts with light Engraving structural patterns is a key material that affects the production efficiency of semiconductor processes.

Photoresist is mainly divided into two types: Positive Photoresist and Negative Photoresist

- Positive photoresist: The part that is not exposed to light will not dissolve in the photoresist developer. The photoresist illuminated area will dissolve in the photoresist developer. The molecular chain will be broken and the solubility will increase. It is mainly used in semiconductor processes that require high pattern fineness.

- Negative photoresist: Negative photoresist is the opposite of positive photoresist. It will not dissolve in the photoresist developer after being illuminated. The molecules are cross-linked and the solubility becomes smaller. It is the earliest photoresist used in the photolithography process.

Explanation of the differences between photoresist and photoresist remover

Photoresist and photoresist remover have different uses. The differences between them are as follows:

- Process role: The main purpose of photoresist is to make graphics; photoresist removal uses peeling, dissolution, etc. to complete the photoresist removal process.

- Differences in ingredients: Photoresists are generally polymer materials; photoresist removers are generally organic solvents or aqueous solutions.

How to use photoresist

Take the semiconductor manufacturing process as an example. The photoresist undergoes polymer chain scission or cross-linking reactions under different light source conditions, and is combined with the development process to create patterns to facilitate subsequent diffusion, etching, and thin film processes, and then remove the light. The resist removes the photoresist layer and cleans the wafer surface impurities.

What are the uses of photoresist remover and how to apply it?

Photoresist remover can remove photoresist, clean and other processes without damaging specific materials, including:

- Remove surface impurities such as process residues and particles

- Photoresist after stripping process

- Cleaning wafer surface

Take the non-NMP, non-DMSO, and non-TMAH environmentally friendly photoresist remover products used by Chip Enterprise Co., Ltd. as an example. The main ingredients are organic solvent-based removers made from organic bases and organic acids. The resist can remove positive photoresist, negative photoresist, and dry film photoresist, and is suitable for industry processes such as Discrete Device, LED, IC, bumping, and III V. Assist companies to create semiconductor manufacturing processes that comply with EU REACH environmental standards, implement sustainable transformation of the EGS industry, and ride on the circular economy trend of green energy development.

Environmentally friendly photoresist remover|Chipu Enterprise Co., Ltd.

Chipu Enterprise Co., Ltd. E-CHEM is one of the few channel service providers with the capabilities of formula development, customized production and quality inspection, providing services including Environmentally friendly photoresist remover and other complete one-stop shopping materials with stable quality meet your material needs.

We attach great importance to pursuing the improvement of process technology and innovative industrial development prospects with our customers. We have professional-scale laboratories, clean rooms and inspection instruments. Through R&D and technology The team's professional capabilities will meet a series of customized needs of customers for local production, supply, and product development in Taiwan.

In line with the corporate philosophy of integrity, dedication, and sustainable management, Zhipu Enterprises continues to optimize existing products, develop new materials, and actively implement corporate social activities, hoping to become the best cooperation in the minds of customers and suppliers. partner.